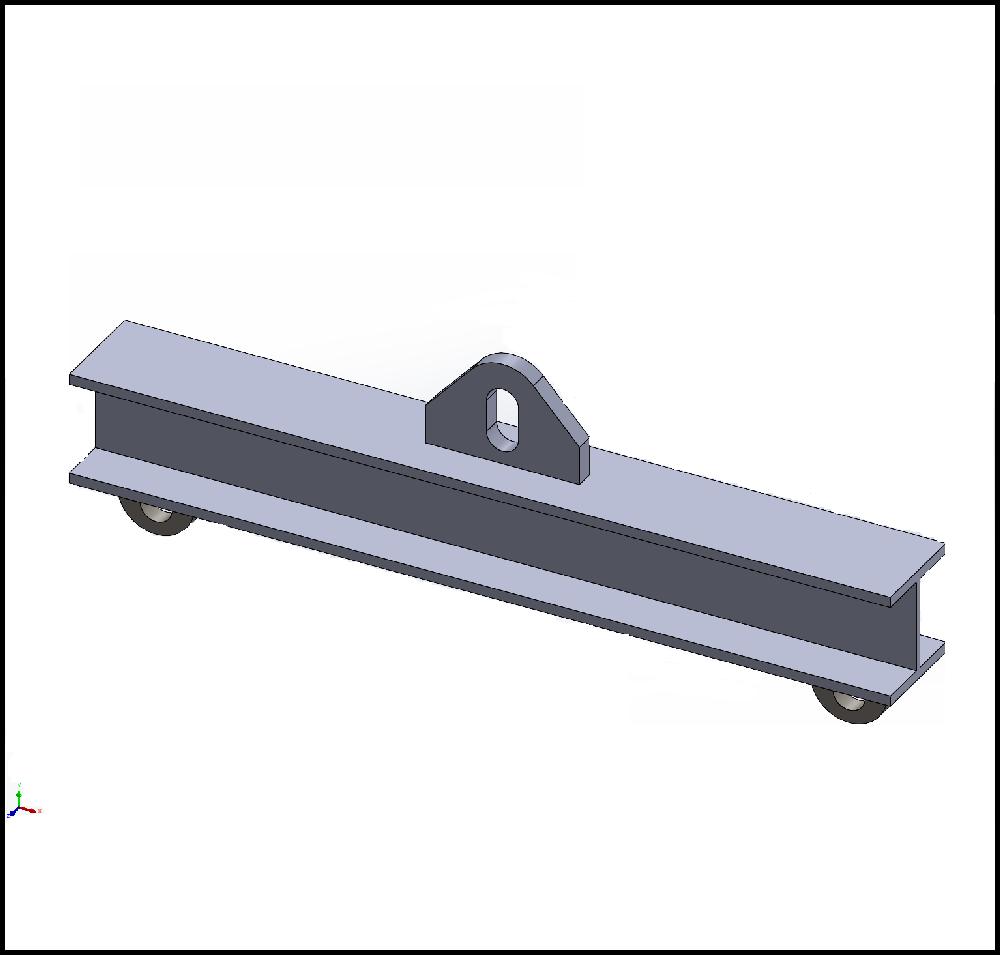

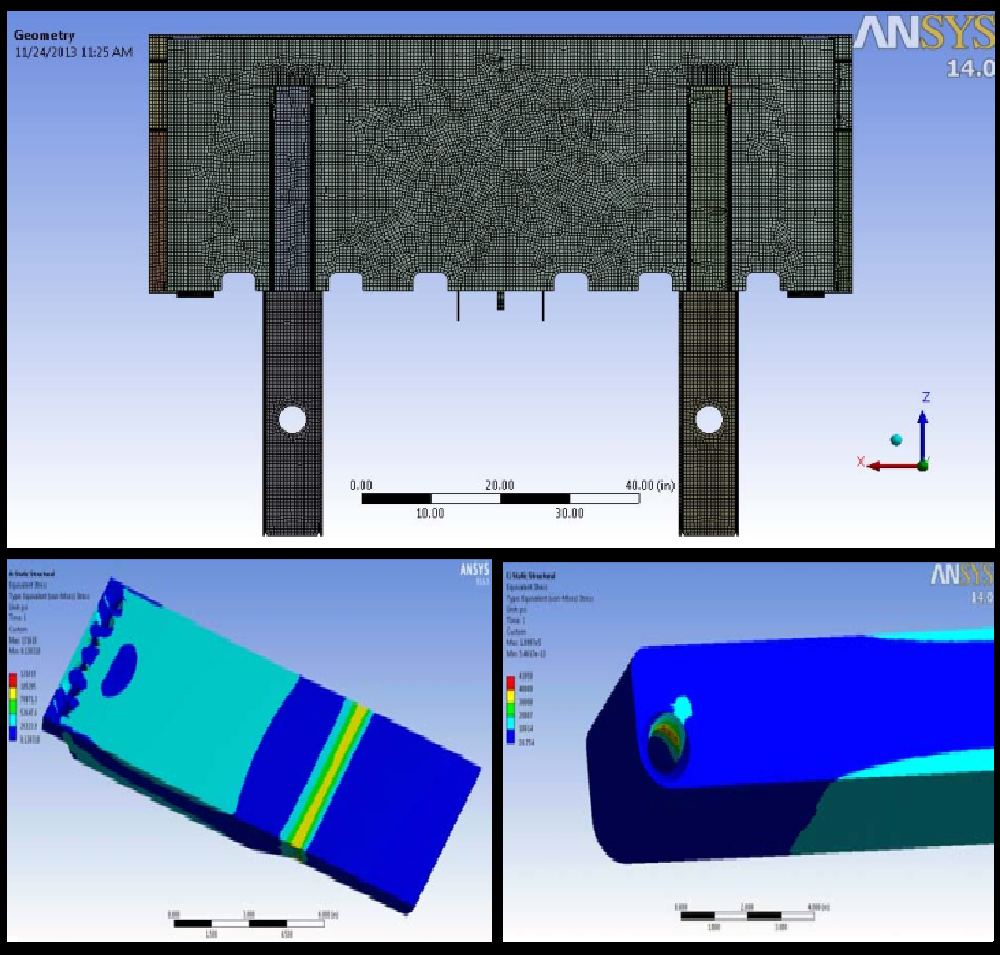

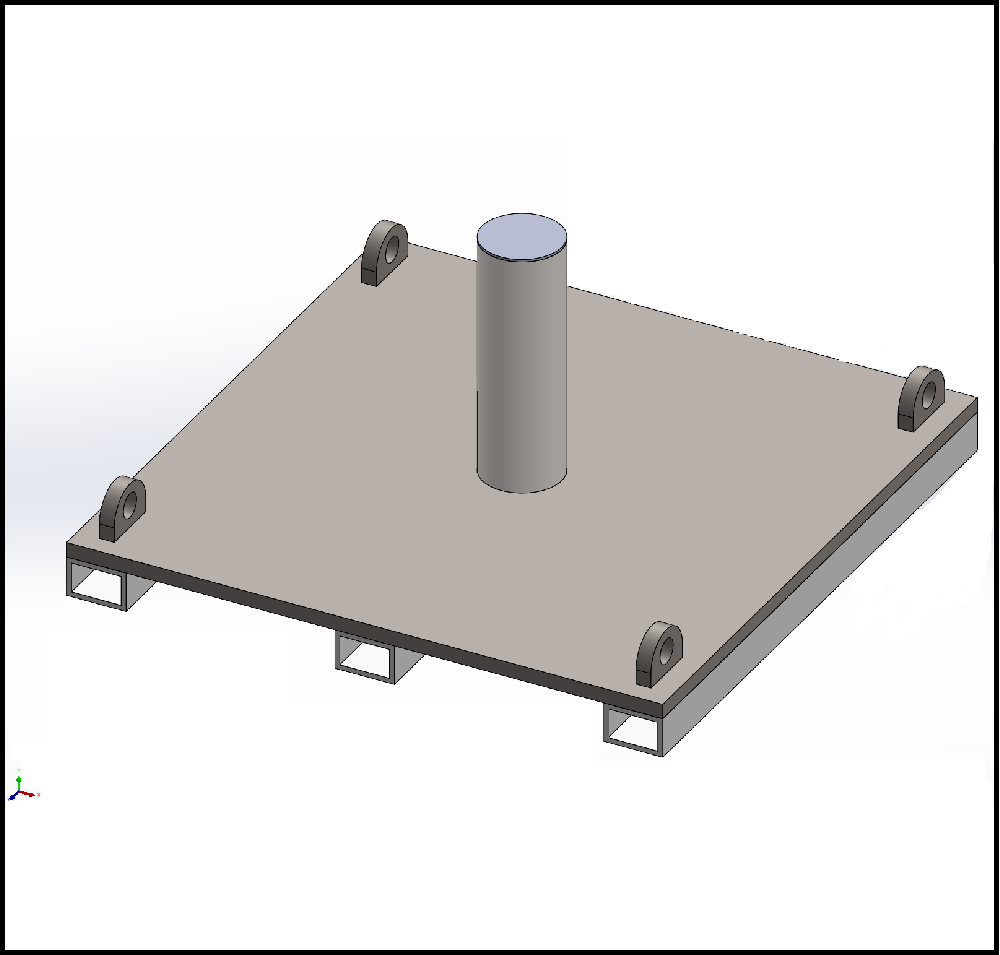

Lifting Device

Our client was in need of a lifting device rated for 10,000 lbs as well as a PE stamped drawing to assist in fabrication. The initial client specified design included off-the-shelf lifting attachments. However, it was made aware that these were outside of their initial budget and a more economical design was needed from our team. EESI's engineering team was able to design a cost-effective lifting device that saved our client time and money. We also generated an engineering drawing that we PE stamped and was used for fabrication.