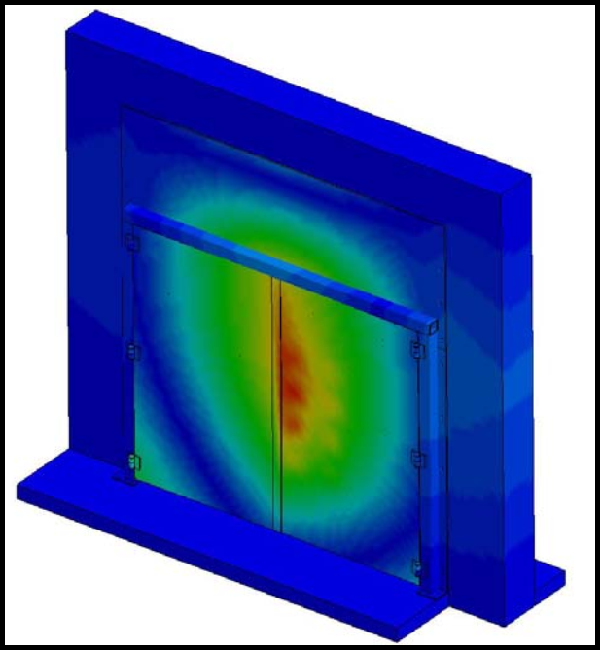

Tornado Door

In the process of implementing directives from the Nuclear Regulator Commission (NRC), our client needed to design a tornado door for the facilities' FLEX equipment storage building. The door was required to resist the missiles included in the plants Final Safety Analysis Report (FSAR) and remain operable. Our engineering team adopted the use of both hand calculations and LS-DYNA to design and analyze an economic and easily manually operated tornado door exceeding FSAR and NRC requirements. Detailed engineering drawings were also provided to assist in the fabrication of the new door. By employing EESI on this project the client was able to purchase two doors for less than the price of a single off-the-shelf tornado door, including custom design.